The Queensland mining industry has been labelled as stuck in a ‘fatality cycle’. This comes after a report was released this week by Dr. Sean Brady, titled ‘Review of all fatal accidents in Queensland mines and quarries from 2000 to 2019’. The report was commissioned by the Queensland Government in 2019 after experiencing a record amount of deaths in mining that year (5).

Eleven recommendations are made in the report, each contributing to a wider solution for the mining industry to prevent these deaths. Three speak specifically to the potential of new technology to break the cycle. These include acknowledging there is a problem by investing in solutions, challenging the “fatalist” mindset that believes mining is unavoidably dangerous and ensuring trained workers are deployed to the right jobs.

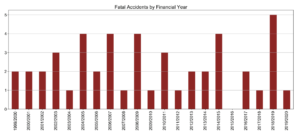

The number of fatalities that occurred in each financial year for the review period (Brady Report)

The number of fatalities that occurred in each financial year for the review period (Brady Report)

The Report

Dr Sean Brady is an author and forensic structural engineer. His report reviews the 47 deaths that have occurred in Queensland’s mines and quarries from 2000 to 2019. It divides each incident into categories of “cause” and places an organisational focus on how certain scenarios, that result in worker fatalities, are created by multiple factors combining over time rather than “freak accidents”. The report’s release comes at the same time as Queensland’s Mining Minister Anthony Lynham is proposing new industrial manslaughter legislation. A similar push for this legislation occurred in Western Australia in 2019. Lynham was also the Minister who commissioned the fatalities report in the first place. The eleven recommendations (summarised) in the report were:

- The industry should acknowledge that a “fatality cycle” exists

- Recognise that fatalities are typically a combination of everyday factors and avoid simplifying incident investigations to a single cause

- Focus on appropriate worker training for specific tasks

- Better supervision whilst undertaking tasks

- Ensure the effectiveness and enforcement of controls to manage hazards

- Adopt the principles of High-Reliability Organisational theory to reduce the rate of Serious Accidents and fatalities

- Ensure the Regulator plays a key role in disseminating the lessons learned from the incident and fatality data it collects

- Develop a new and greatly simplified incident reporting system

- Use the Lost Time Injury Frequency Rate (LTIFR) as a safety indicator rather than Lost Time Injuries (LTIs)

- Adopt the Serious Accident Frequency Rate as a measure of safety in the industry.

- Adopt the High Potential Incident Frequency Rate as a measure of reporting culture in the industry.

Acknowledging the ‘Fatality Cycle’

Step one for the industry is acknowledging that the ‘fatality cycle’ exists in the first place. Dr Brady expressed in his report that an overhaul of the industries attitude and approach towards safety is necessary to better protect workers.

“If the industry continues to take a similar approach to safety, using the same philosophies and methodologies adopted over the past 19 years, then similar safety outcomes are to be expected.”, he said.

The industry is ripe for new methods of workforce management that utilise technology to minimise the risk of worker fatalities from beginning to end. If stakeholders are serious about breaking the cycle, simply acknowledging it with words isn’t enough to redefine the approach to worker safety. Investing in solutions and technology that are creating a new industry standard for safety will result in new safety outcomes, rather than allowing the past to repeat itself.

Recognising the root of the problem

The report identifies a 'fatalist' mentality that exists within the mining industry. This means that accepting mining to be a dangerous industry with unavoidable fatalities, makes it easier to accept them as “freak accidents” and mask the underlying system failures. In his investigations, Brady discovered that “the causes of fatalities are typically a combination of banal, everyday, straightforward factors, such as a failure of controls, a lack of training, and/or absent or inadequate supervision.” A contrast is made in the report to the airline industry, where the public believes air travel to be safe and do not expect incidents, despite the many numerous hazards the industry must overcome.

The action here is for mining companies, regulators and government to utilise information, tools and systems to recognise the underlying issues that lead to worker fatalities. If a bigger picture approach is taken towards the safety processes in place, from verification of tickets to assignment of tasks on-site, then incidents can be pre-empted.

Matching trained workers with tasks

“A total of 17 of the 47 fatalities involved a lack of task-specific training and/or competencies for the tasks being undertaken. A further 9 had inadequate training. These tasks were often undertaken at the direction of supervisors or others who were aware of these deficiencies.”

These numbers highlight the urgent need to simplify training & qualifications management, and better track worker competency. In MyPass® Global’s experience working for and with large service providers in the Australian resources industry, managing the competency of a large, transient workforce has always been a major challenge. In the past, this has led to multiple spreadsheets containing massive amounts of private data, documents being lost between numerous emails and an inability to integrate internal platforms so they can 'talk' to each other. Having the assurance that every worker on-site is appropriately trained and qualified to complete the jobs assigned to them is something that keeps many operational leaders awake at night. MyPass® is working with more than 180 companies in the resources sector and is in parallel empowering individuals with a ‘single source of truth’ work passport, designed to reduce the risk of compliance gaps. We are also connecting Registered Training Organisations such as ERGT and IFAP with workers and companies to create an ecosystem that uses shared data to fill compliance 'blind spots'.

Technology like MyPass® is no ‘silver bullet’ to break this cycle, but we are passionate about the role we can play to help workers return safely home at the end of the day. If these types of new-age solutions aren’t embraced by the industry, it is likely that the cycle will continue as it has for the past twenty years.